Have you, or someone you know, ever been in need of an organ transplant? If so, then you understand how long it can take to wait for an available organ. In reality, the wait can take months or years, depending on your condition. The wait includes being be moved to the top of the critical list and then waiting for a phone call or a page saying that a donor has been found. And while the wait is painful, the organ often comes at the expense of a donor’s life. With new technology like the 3D printer, the excruciating wait for organ donors may soon be over.

Table of Contents

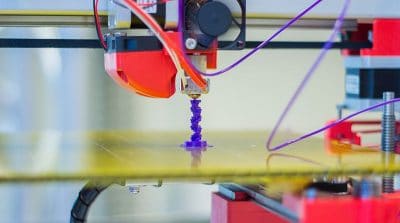

The Day of the 3D Printer

Since the invention of the first 3D printer in 1983, the technology has increased to the point where you can print almost anything you can imagine. With the right programming, a 3D printer can create everything from sculptures and cups to architectural models, working guns, and now body parts. KSL wrote, “The birth of 3-D scanning technologies combined with organic inks and thermoplastics has enabled the “bioprinting” of a range of human body parts to accommodate a wide range of medical conditions.” Scientists have already printed skulls, prosthetic limbs, eyes, ears, and noses that have been surgically implanted. And while some of the more complex organs are being printed as patient-specific models that can be used by surgeons as guides, it is likely that it won’t be long before working hearts and other complex organs can be printed and transplanted.

So What are We Waiting For?

CNN recently wrote an article discussing the challenges that lie between the idea and the reality of printing complex organs. They began the article by saying:

Before any organ can be engineered — whether it’s printed or built by hand — there is much groundwork that must be accomplished. Vital to the process is a thorough understanding of cell biology. Scientists must determine not only what types of cells to use, but how to expand them in the lab and how to keep them alive and viable throughout the engineering process. Do they need to be imbedded in biocompatible material? If so, which biomaterial is most suitable? The bar for success is high — the structures we engineer must function like native tissue.

Dr. Anthony Atala commented on how his team has already engineered airways, bladders, blood vessels and urine tubes that have been successfully implanted. And while some organs have been created by hand through a slow process of layering biomaterial and cells together, a printer working off of a computer image of the patient’s actual organ would be much more accurate and functional. And once the problem of creating a stable organ that will not be rejected or shut down before being implanted can be resolved, the world of long transplant waits and donor cards will come to an end.

How does this Affect You?

While the printing of stable organs may still be years away, there are already lots of medical uses of 3D printers which have been tested and approved for medical use. Doctors are using printers to print muscle, tissue, and bone for the use of facial reconstruction. 3D printers have been used to replace skulls and improve vision where eyesight formerly didn’t exist. And with the rate of improvement in the 3D printing world, it may not be long, or it may already be possible, for your injury to be healed or helped by a 3D printer.

Success Stories to Take Home

These stories were reported in the KSL article that was previously cited in this article:

- Doctors at University Medical Center Utrecht, in Holland, have reported successfully performing the first surgery to completely replace a patient’s skull with a tailor-made plastic version that was 3-D printed. The patient had a chronic bone disorder that caused her skull to be 5cm thick. The hospital said the condition had caused her to lose her vision and ultimately would have killed her. Three months after the operation the patient regained her vision and was able to return to work.

- Batch-printing of up to 150 prosthetic eyes an hour has become a reality according to UK-based company Fripp Design and Research. The mass-production technique promises to speed up the manufacture of eye prostheses and drive down the cost. Printing each eye with slight variation in color is intended to produce better aesthetic results. The aim is to ensure more affordable eyes for the developing world with countries such as India reportedly showing interest in the products. The company, in collaboration with the UK’s Manchester Metropolitan University, hopes to implement the use of its printed eyes within the next year.

- James Yoo at the Wake Forest School of Medicine is developing a printer that will print skin straight onto the wounds of burn victims. The “ink” they’re using consists of enzymes and collagen which once printed are layered with tissue cells and skin cells which combine to form the skin graft. The team plans on developing portable machines to print skin directly onto wounds in remote and war-torn settings.

- Thermoplastics have led the way in the growth of printable hands, arms and even individual fingers. Richard Van As is one of those producing affordable hand and finger prostheses with his South Africa-based company Robohand. The team is creating functional fingers for use on amputated hands by combining the printing of the thermoplastic polylactide with aluminum and stainless steel digits to create a functioning mechanical finger.

Photo copyright to Jonathan Juursema